In today’s fast‑moving manufacturing landscape, the drive to reduce energy consumption, increase precision, and embed intelligence into factory floor equipment has pushed motor technology into an exciting new arena. Two pivotal motor types—gear motors and regular (often referred to as “plain” or “direct‑drive”) motors—are undergoing transformative upgrades. Understanding how each evolves and where they shine allows plant managers to select the right tool for a given application and to anticipate future industry shifts.

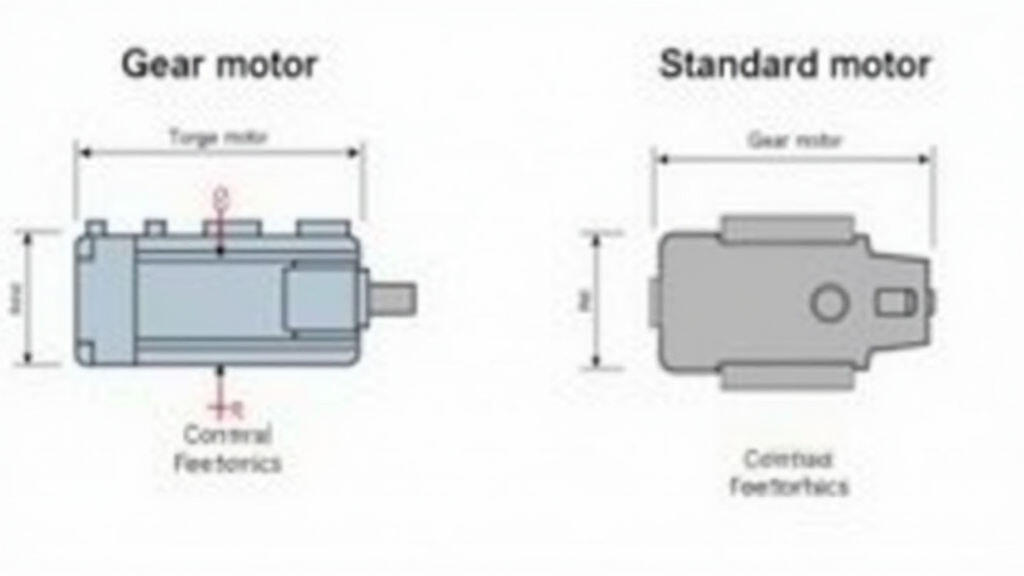

A gear motor couples a motor and a gear train into a single unit. This design delivers high torque at low speeds directly to a load, eliminating the need for separate gearboxes. Gear motors are celebrated for their compactness and reliability in high‑torque applications.

A regular motor—typically a DC or induction motor—produces speed and torque that must be modified outside the motor body using gearboxes, couplings, or other mechanical systems. While more modular, this approach often results in larger assemblies and higher maintenance.

Modern gear motors are no longer simple “off‑the‑shelf” units. They are growing into smart, energy‑efficient power hubs that seamlessly integrate with factory automation.

Today's gear motors embed microcontrollers that communicate real‑time torque, position, and health data to Plant Information Management Systems (PIMS). This enables predictive maintenance, reducing unplanned downtime by up to 30% in high‑volume environments.

In addition to software, gear materials are shifting toward composites and advanced alloys with lightweight, high‑strength properties. Surface treatments such as cryogenic hardening and diamond‑like carbon (DLC) coatings cut gear wear, extending service life and tightening energy budgets.

Integrating regenerative braking turns motor kinetic energy back into the plant grid during deceleration. Industry pilots report energy rebates of 10–15% for conveyor and robotic joints, a game‑changer for sustainability targets.

Even traditional motors aren’t left behind. Advances are making them more adaptable, efficient, and embedded.

Replacing brushed designs with BLDC motors reduces friction, improves speed regulation, and cuts maintenance costs. Coupled with field‑oriented control (FOC), these motors can now match the precise torque profiles once unique to gear motors.

Standardized motor‑gearbox assemblies, complete with magnetic couplings, allow quick swaps or upgrades. An operator can replace a worn gearbox without removing the motor, minimizing machine downtime.

Regular motors now carry embedded sensors (temperature, vibration, current) that feed into AI models. These models detect subtle patterns indicating impending faults, enabling preemptive service and prolonging machine life.

Choosing between a gear motor and a regular motor depends on application specifics: torque requirements, speed tolerance, control precision, and economic factors.

Real‑world implementations illustrate how these trends are reshaping production lines.

Integrated gear motors drive high‑speed box forming and sealing, while sensor‑rich BLDC motors maintain rhythm across multiple stations, reducing errors and boosting throughput.

Robotic arms now rely on micro‑controlled gear motors for precise torque while moving heavy components. Simultaneously, BLDC motors feed conveyor belts that transport parts, benefiting from improved energy usage and low maintenance.

Lightweight gear motors with regenerative braking enable cobots to share workspaces safely, drawing power back when decelerated and ensuring smooth, human‑friendly interactions.

The line between gear motors and regular motors is blurring. Hybrid units are emerging: a brushless motor paired with a compact planetary gear set inside a single casing. These offer the torque of a gear motor and the speed efficiency of a regular motor, all while staying connected to an Industrial Internet of Things (IIoT) backbone.

Energy harvesting and machine learning integration will further enhance autonomy, making the factory floor progressively smarter and greener.

The manufacturing sector’s push for smarter, more efficient equipment has redefined both gear motors and regular motors. Gear motors, now equipped with digital twin technology and regenerative braking, excel in high‑torque, space‑constrained roles. Regular motors, upgraded with brushless designs and AI‑driven diagnostics, shine in speed‑centric and modular applications.

Understanding these evolving characteristics allows plant leaders to strategically integrate the right motor type into each process. The future points toward hybrid, AI‑enhanced units that combine the best of both worlds—optimizing performance, reducing costs, and accelerating sustainability goals.

By adopting these innovative motor trends, manufacturers can elevate productivity, lower operational footprints, and stay ahead in an increasingly competitive marketscape.

Leave A Reply

Your email address will not be published. Required fiels are marked